PA 6.6 Fiber and Yarn and Water Cooling process

• Wide range of fiber count from 15 to 600 dtex or dpf

BIBIELLE FIBER Company owns a unique and exclusive technology for manufacturing the highest quality PA 6.6 fiber and yarn through a water cooling process.

Thanks to this process, the fiber can be modulated according to customers’ needs, offering a unique quality standard.

Why is the watercooling process qualitatively higher?

Thanks to the water cooling process that BIBIELLE uses throughout the entire production, yarns and fibers have the right balance, are manageable and adaptable, within the crystal and amorphous parts that make up the material.

This results in an optimum dyeing affinity, expressed in brightness and solidity of the color of the yarn definitely unique.

The technology available to BIBIELLE, further allows controlling and adjusting the crystallization rate of the polymer, that is the speed at which the vitreous transition takes place and the passage from liquid to solid state of the polyamide.

Depending on customers’ needs and various applications, best standards may be identified to achieve custom color target.

The dyeing in mass combined with controlled and modifiable water cooling process make BIBIELLE‘s yarns and fibers unique in the PA 6.6 industry.

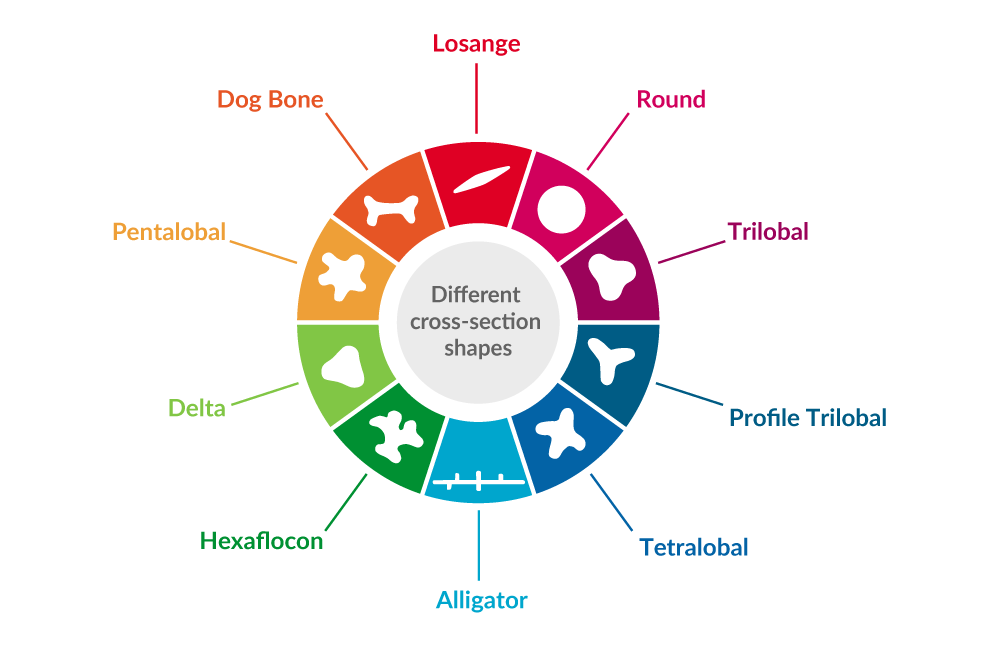

• Different cross-section shapes

• Available in bright, semi-dull and dull

Elongation, elasticity and tenacity are technical and mechanical characteristics well known to those who use yarns or fibers of synthetic materials.

In the classical and traditional spinning mills, a close relation exists between the residual elongation of the yarn and the tenacity of the same, or rather how much force expressed in d/tex the yarn is able to absorb before it breaks.

The two variables are inversely proportional and are obtained by the elongation of the yarn during processing. The more the yarn is stretched, the higher the tenacity and low the elongation;

decreasing stretching increases elasticity and at the same time decreases tenacity.

Bibielle’s unique technology, that employs water cooling process, allows going beyond this concept universally known and typical of the typical BCF spinning mills through air cooling, since depending on water temperatures used during cooling post extrusion, different chemical mechanical characteristics are conferred to the yarns therefore arriving at the elongation process with products extremely elastic or extremely rigid. This means that during the elongation process, it is possible to obtain medium high tenacity values over 30 cNW/tex and, at the same time, not refrain from elongation values over 60/80%.

BCF yarn and fiber users are normally constrained to compromise, identifying tenacity/elongation values that are the most suitable for their applications. This choice, unfortunately, is bound to the close and constant correlation between the two elements. Should the users’ application require a different affinity between elongation and tenacity, Bibielle’s technology could prove to be decisive and innovative.